Under linear elastic fracture mechanics (LEFM), the maximum circumferential stress criterion is applied as a direction criterion. The present study was carried out for two geometries, namely a cracked plate with four holes and a plate with a circular hole, and an edge crack with different pre-crack locations. If the hole is close enough to the crack path, the crack may stop at the edge of the hole, resulting in crack arrest. The presence of a hole near a propagating crack causes a deviation in the crack path.

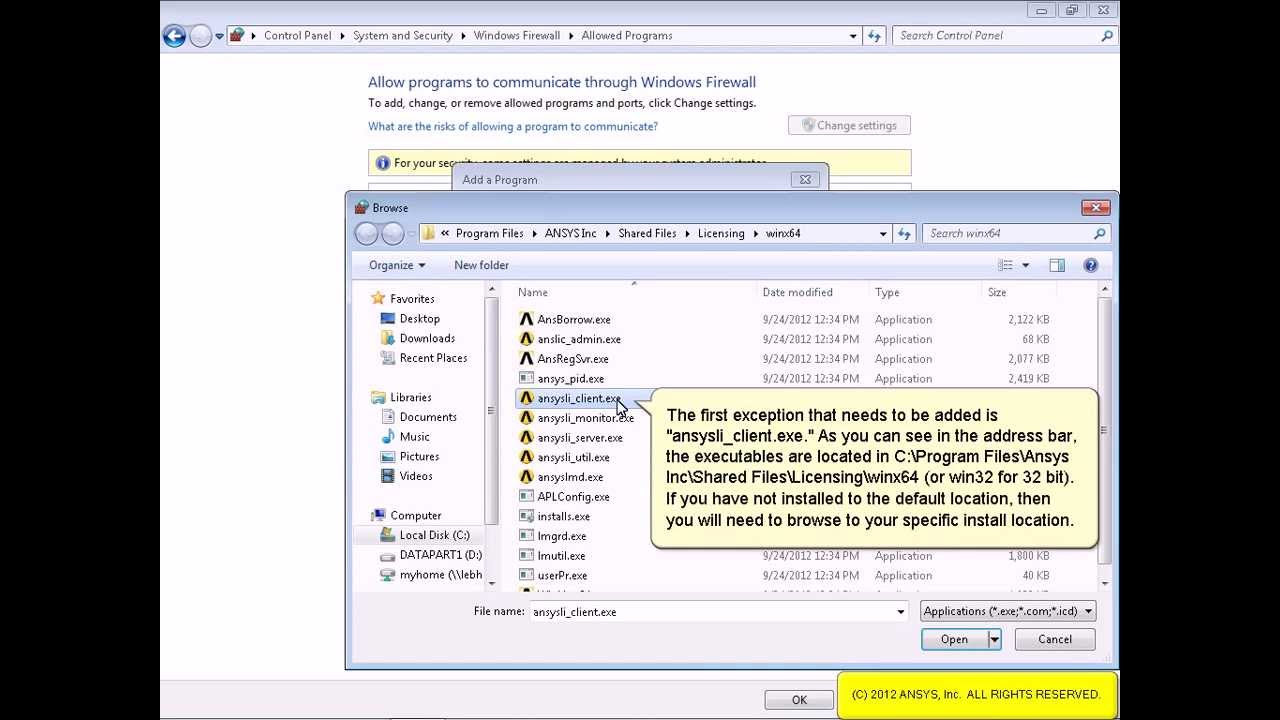

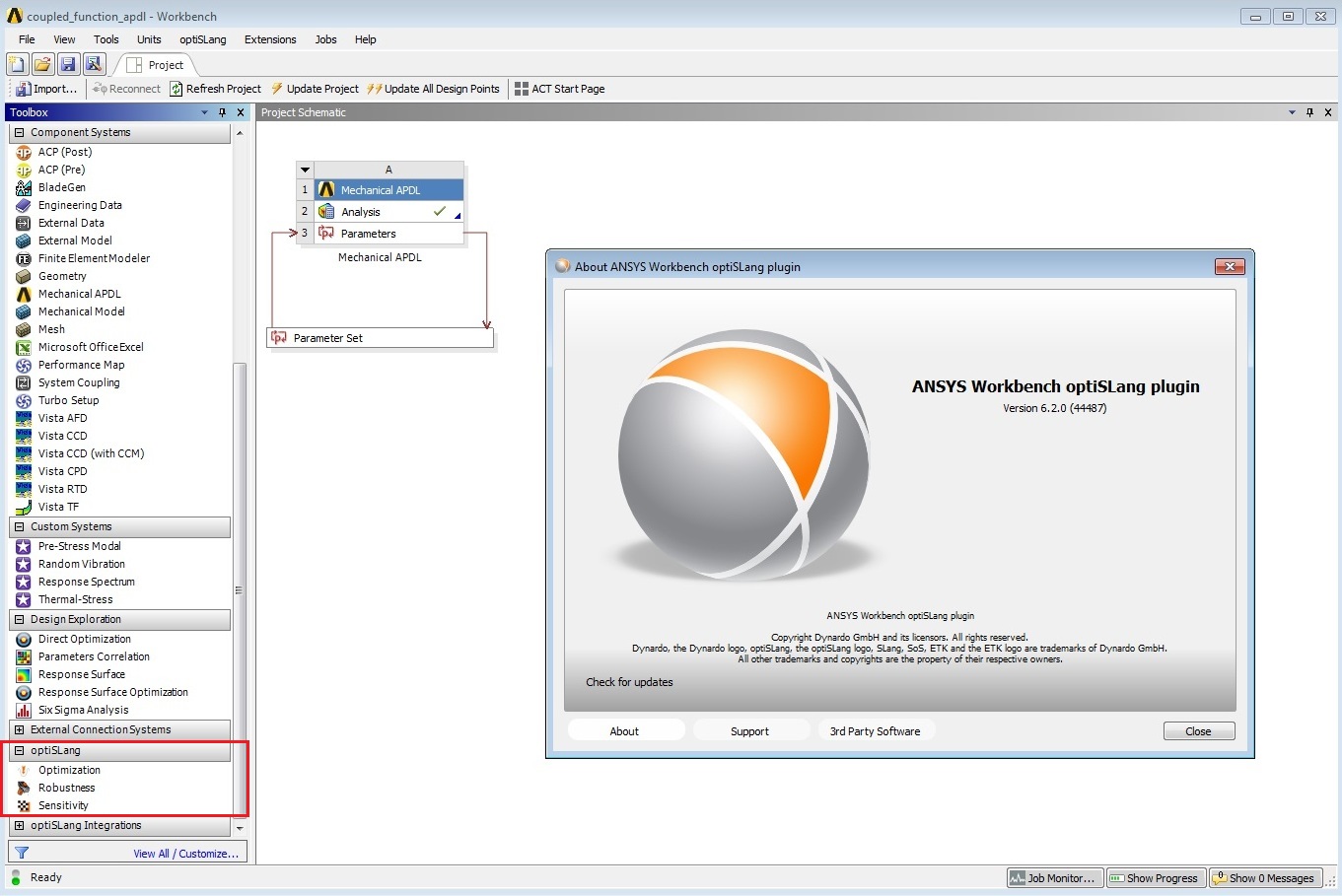

For this purpose, ANSYS Mechanical R19.2 was introduced with the use of a new feature known as Separating Morphing and Adaptive Remeshing Technology (SMART) dependent on the Unstructured Mesh Method (UMM), which can reduce the meshing time from up to several days to a few minutes, eliminating long preprocessing sessions. The influence of the holes’ position and pre-crack locations in the crack growth direction were investigated. The aim of this paper was to present a numerical simulation of a crack growth path and associated stress intensity factors (SIFs) for linear elastic material.

0 kommentar(er)

0 kommentar(er)